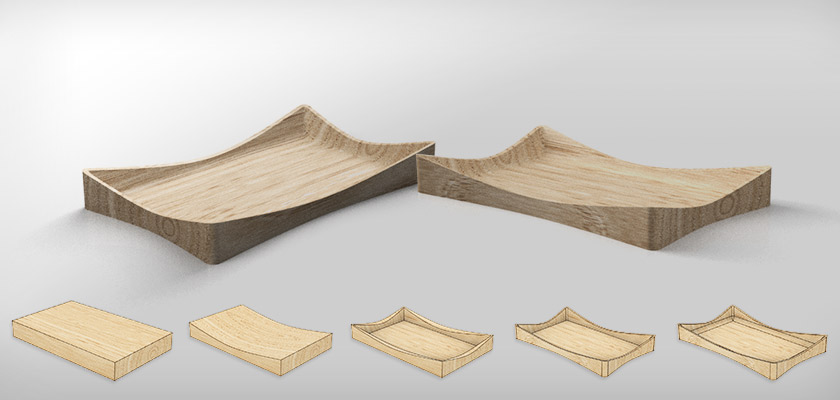

In this article we will take look at how to make a nice original wooden bowl using a CNC machine and several types of router cutter bits from the IGM product range.

We chose ash wood as our material. Ash has one of the hardest woods of all broadleaved trees with a beautiful grain that will truly stand out on the final product. The 3D modelling was done in the Fusion 360 software.

In collaboration with LB CNC Woodworking (Facebook).

Here you can watch a video of how the bowl was made.

First we need to flush the surface of the workpiece using the Surfacing Router Cutter on both sides. The router has three cutting wings which ensure a perfectly smooth cut. By using the Surfacing Router Cutter on the CNC a very similar result is achieved as with planing and dragging.

CNC parameters used for

- Spindle Speed: 12 000 RPM.

- Cutting Speed: 3,6 m/min.

- Feed Rate: 0,1 mmm.

In the next step we conduct a rough shaping of the bowl. For that we will use the Downcut Spiral Router Cutter. This router cutter is made entirely of first-grade carbide and its blades ensure an excellent quality finish on the upper edge of the workpiece. We will also use this router cutter to route the bottom of the final product.

CNC parameters used for

- Adaptive Machining.

- Spindle Speed: 15 000 RPM.

- Cutting Speed: 4,5 m/min.

- Feed Rate: 0,15 mm.

- Optimal Load: 3,2 mm.

- Maximum Roughing Stepdown: 8 mm.

- Fine Stepdown: 1 mm.

In the next stage we exchange the Downcut Spiral Router Cutter for the Round Nose Upcut Spiral Router Cutter - we will use it to clean off the edges left from gradual routing in previous steps. We work the edges until the lines of the bowl are perfectly smooth. Next we use the round nose cutter again to smooth down the other side of the bowl.

CNC parameters used for

- Parallel Machining.

- Spindle Speed: 18 000 RPM.

- Cutting Speed: 3,6 m/min.

- Feed Rate: 0,1 mm.

- Stepover: 0,3 mm.

Smoothing Down the Edges with the Flush Trim Bit

The last thing now is to flush the stumps which held the workpiece in place. We will do that on a router table using the flush trim bit in a router.

Finally we treat the workpiece with a colourless

oil so that the grain is nicely visible.

LB CNC Woodworking

Design and production of wooden accessories

Each piece is an original

LB CNC Woodworking makes custom original wooden items.